Proud Suppliers For

Steam Valve Range

-

Control Valves

Control valves play a crucial role in managing the flow and pressure...

-

Saftey Valves

Safety valves are essential components in steam applications, designed to release excess...

-

Globe Valves

Globe valves, ideal for regulating steam flow in various industrial processes, offer...

-

Butterfly Valves

Butterfly valves are ideal for regulating steam flow in industrial settings, offering...

-

Pressure Regulating Valves

Pressure regulating valves are essential in steam systems, ensuring consistent operational pressures...

Pressure Regulating Valves

Pressure regulating valves are essential in steam systems, ensuring consistent operational pressures...

Heat Extension Kits

What our customers think:

Get in touch-

Maintenance Manager, Food Processing Plant

"Steam Valve has been our go-to supplier for over two years. Their team understands the urgency behind steam applications and always delivers top-quality valves on time. Excellent service from start to finish."

-

Engineering Supervisor, Chemical Manufacturer

"We needed a fast turnaround on a valve replacement for a critical steam line. Steam Valve not only had the part in stock, but it was delivered the next day. Can’t recommend them highly enough."

-

Project Engineer, Industrial Boiler Systems

"The level of technical support from Steam Valve has been outstanding. They helped us select the right control valve for our high-pressure steam system and it’s been running perfectly ever since."

-

Operations Manager, Pharmaceutical Facility

"We’ve worked with several suppliers over the years, but Steam Valve stands out. High-quality products, expert advice, and a genuine understanding of steam systems. They’re now our first call."

Ari Armaturen Steam Traps

Ari Armaturen Steam Traps offer reliable condensate removal and energy-efficient performance across a wide range of steam systems. Built for precision and durability, these traps ensure optimal system pressure, prevent water hammer, and support consistent heat transfer in demanding industrial environments.

-

ARI CONA TD Steam Trap (Thermodynamic, PN63, Screwed Connections)

Regular price From £267.84 GBPRegular priceUnit price / perARI CONA TD Steam Trap (Thermodynamic, PN63, Screwed Connections)

Regular price From £267.84 GBPRegular priceUnit price / perARI CONA TD Steam Trap (Thermodynamic, PN63, Screwed Connections)

Regular price From £267.84 GBPRegular priceUnit price / per -

ARI CONA SC Ball Float Steam Trap (Forged Steel Body, Flanged PN16)

Regular price £473.76 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Forged Steel Body, Flanged PN16)

Regular price £473.76 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Forged Steel Body, Flanged PN16)

Regular price £473.76 GBPRegular priceUnit price / per -

ARI CONA SC Ball Float Steam Trap (Forged Steel Body, Screwed Connections)

Regular price £351.36 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Forged Steel Body, Screwed Connections)

Regular price £351.36 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Forged Steel Body, Screwed Connections)

Regular price £351.36 GBPRegular priceUnit price / per -

ARI CONA SC Ball Float Steam Trap (Nodular Iron Body, Flanged PN40)

Regular price From £686.88 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Nodular Iron Body, Flanged PN40)

Regular price From £686.88 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Nodular Iron Body, Flanged PN40)

Regular price From £686.88 GBPRegular priceUnit price / per -

ARI CONA SC Ball Float Steam Trap (Nodular Iron Body, Screwed Connections)

Regular price From £639.36 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Nodular Iron Body, Screwed Connections)

Regular price From £639.36 GBPRegular priceUnit price / perARI CONA SC Ball Float Steam Trap (Nodular Iron Body, Screwed Connections)

Regular price From £639.36 GBPRegular priceUnit price / per

Explore our blog

Take a look at what’s new on our Steam Valves blog — from product insights and technical guides to the latest updates in steam applications, it’s the place to stay informed and make smarter decisions for your systems.

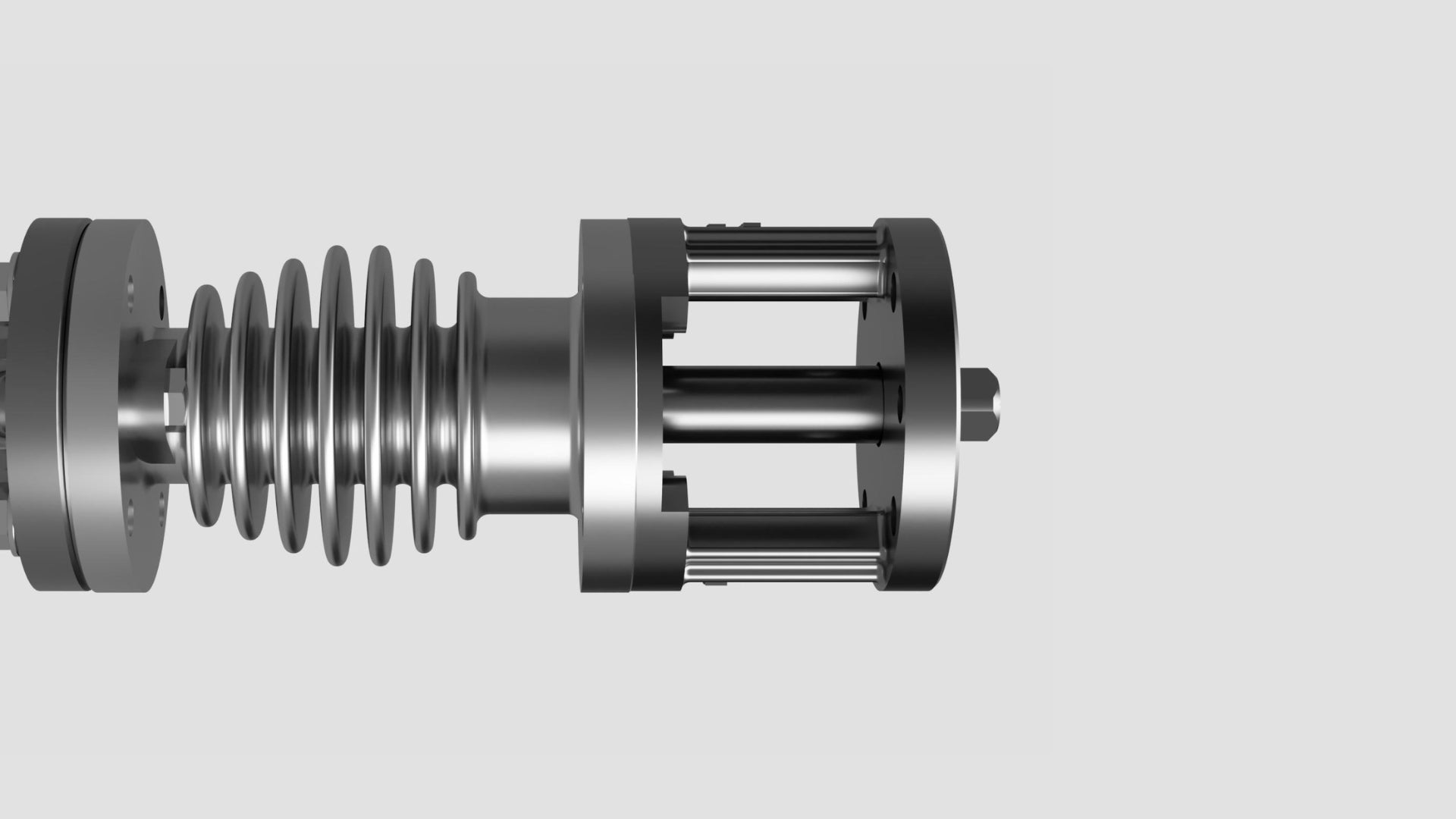

Ari Armaturen Isolation Globe Valves

Ari Armaturen Globe Valves are engineered for precision control in steam and industrial flow applications. Designed for durability and tight shut-off, these valves deliver reliable modulation and isolation, making them ideal for high-pressure and high-temperature systems.

-

FABA+ Bellows Sealed Globe Valve (Flanged PN16, Nodular Iron Body)

Regular price From £400.32 GBPRegular priceUnit price / per -

FABA+ Bellows Sealed Globe Valve (Flanged PN25, Nodular Iron Body)

Regular price From £433.44 GBPRegular priceUnit price / per -

FABA+ Bellows Sealed Globe Valve (Flanged PN40, Cast Steel Body)

Regular price From £686.88 GBPRegular priceUnit price / per -

Ari Armaturen FABA+ Bellows Sealed Globe Valve (Flanged PN40, Stainless Steel Body)

Regular price From £1,388.16 GBPRegular priceUnit price / per

Newsletter

Sign up to receive our latest news & offers